- View Mobile Number

moxcrane@gmail.com

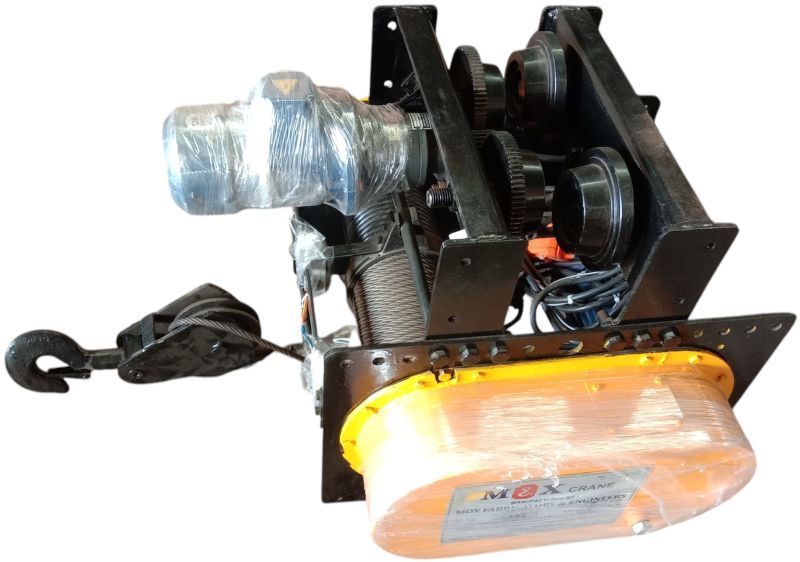

Wire Rope Chain Hoists

Leading Manufacturers, Wholesaler, Trader, Distributor and Exporters of 1 Ton Wire Rope Hoist, 2 Ton Electric Wire Rope Hoist, 3 Ton Electric Wire Rope Hoist, 5 Ton Electric Wire Rope Hoist, Base Mounted Wire Rope Hoist, Curvature Electric Wire Rope Chain Hoist, Electric Wire Rope Hoist, Electrical Wire Rope Hoist, Flame Proof Electric Wire Rope Chain Hoist, Girder Electric Wire Rope Hoist, Heavy Duty Wire Rope Hoist, Low Headroom Electric Wire Rope Hoist, Material Handling Electric Wire Rope Hoist, Monorail Wire Rope Hoist, Motorised Wire Rope Hoist and Single Beam Wire Rope Hoist from Ahmedabad.

| Business Type | Manufacturer, Supplier |

| Brand Name | Mox |

| Loading Capacity | 5-10Tons |

| Driven | Mechanical |

| Country of Origin | India |

| Power | 1-3kw, 3-6kw |

| Automatic Grade | Automatic |

| Voltage | 380V, 440V |

| Application | Weight Lifting |

| Type | Electric Wire Rope Hoist |

| Delivery Time | 5-7 days |

| Packaging Details | Wooden box packing required. |

An electric wire rope hoist is a type of lifting equipment commonly used in industrial and commercial settings to lift and lower heavy loads. It is powered by electricity and uses a wire rope to lift or move loads vertically. The hoist consists of several components, including:

-

Electric Motor: The motor drives the hoist mechanism, providing the necessary power for lifting and lowering loads.

-

Wire Rope: This is the key lifting component of the hoist. The wire rope is wound around a drum, and as the drum rotates, the rope moves, lifting or lowering the load.

-

Hoist Drum: The drum is where the wire rope is wound. The motor rotates the drum to move the rope and lift or lower the load.

-

Hook or Lifting Mechanism: At the end of the wire rope is a hook or another lifting attachment that holds the load.

-

Control System: Hoists are typically controlled by a pendant control, remote control, or a fixed control panel. These systems allow the operator to easily lift or lower loads with precision.

-

Brakes: Electric wire rope hoists have built-in brakes to ensure that the load remains stationary when the motor is not engaged.

- Factories and warehouses: For lifting heavy equipment and materials.

- Construction sites: For moving building materials to higher levels.

- Shipyards: For handling heavy loads and machinery.

- Mining: For hoisting materials in underground mines.

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Electric Wire Rope Hoist |

| Application | Weight Lifting |

| Voltage | 380V, 440V |

| Condition | New |

| Automatic Grade | Automatic |

| Power | 3-6kw |

| Country of Origin | India |

| Driven | Mechanical |

| Loading Capacity | 5-10Tons |

| Brand Name | Mox |

| Delivery Time | 5-7 days |

| Packaging Details | Wooden box packing required |

An electric wire rope hoist is a type of lifting equipment commonly used in industrial and commercial settings to lift and lower heavy loads. It is powered by electricity and uses a wire rope to lift or move loads vertically. The hoist consists of several components, including:

-

Electric Motor: The motor drives the hoist mechanism, providing the necessary power for lifting and lowering loads.

-

Wire Rope: This is the key lifting component of the hoist. The wire rope is wound around a drum, and as the drum rotates, the rope moves, lifting or lowering the load.

-

Hoist Drum: The drum is where the wire rope is wound. The motor rotates the drum to move the rope and lift or lower the load.

-

Hook or Lifting Mechanism: At the end of the wire rope is a hook or another lifting attachment that holds the load.

-

Control System: Hoists are typically controlled by a pendant control, remote control, or a fixed control panel. These systems allow the operator to easily lift or lower loads with precision.

-

Brakes: Electric wire rope hoists have built-in brakes to ensure that the load remains stationary when the motor is not engaged.

- Factories and warehouses: For lifting heavy equipment and materials.

- Construction sites: For moving building materials to higher levels.

- Shipyards: For handling heavy loads and machinery.

- Mining: For hoisting materials in underground mines.

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Mox |

| Loading Capacity | 5-10Tons, 1-5 Tons |

| Driven | Mechanical |

| Country of Origin | India |

| Power | 3-6kw, 6-9kw, 9-12kw |

| Automatic Grade | Automatic |

| Condition | New |

| Voltage | 380V, 440V |

| Application | Weight Lifting |

| Type | Electric Wire Rope Hoist |

| Delivery Time | 3-5 days |

| Packaging Details | Wooden box packing required |

An electric wire rope hoist is a type of lifting device used for handling heavy loads in various industrial and commercial applications. It consists of a motor that drives a wire rope, which is wound around a drum. The hoist is typically mounted on a beam or crane and is used to lift, lower, and move loads vertically or horizontally.

Key components of an electric wire rope hoist include:

- Electric Motor: Powers the hoist mechanism.

- Wire Rope: A strong steel rope that is used to lift and lower heavy loads.

- Drum or Sheave: A drum around which the wire rope is wound, or a series of pulleys (sheaves) that guide the wire rope.

- Hoist Hook: A hook or lifting attachment at the end of the rope to secure the load.

- Control System: A control unit or pendant that allows operators to control the hoist's movement, including the speed and direction.

These hoists are commonly used in environments like factories, warehouses, construction sites, and ports for tasks such as lifting machinery, equipment, or cargo. They offer greater efficiency and precision than manual hoists and are available in various sizes and lifting capacities.

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Mox |

| Loading Capacity | 5-10Tons |

| Driven | Mechanical |

| Country of Origin | India |

| Power | 3-6kw, 6-9kw, 9-12kw |

| Automatic Grade | Automatic |

| Condition | New |

| Voltage | 440V |

| Application | Weight Lifting |

| Use/Application | Industrial use |

| Color | Yellow |

| Power Source | 3 Phase Required |

| Type | Electric Wire Rope Hoist |

| Weight | 100-1000kg |

| Lift Speed | 3-4 Mpm |

| Warranty | 1year |

| After-Sales Service Provided | yes |

| Delivery Time | 5-7 days |

| Packaging Details | Wooden box packing required |

An electric wire rope hoist is a type of lifting device used for handling heavy loads in various industrial and commercial applications. It consists of a motor that drives a wire rope, which is wound around a drum. The hoist is typically mounted on a beam or crane and is used to lift, lower, and move loads vertically or horizontally.

Key components of an electric wire rope hoist include:

- Electric Motor: Powers the hoist mechanism.

- Wire Rope: A strong steel rope that is used to lift and lower heavy loads.

- Drum or Sheave: A drum around which the wire rope is wound, or a series of pulleys (sheaves) that guide the wire rope.

- Hoist Hook: A hook or lifting attachment at the end of the rope to secure the load.

- Control System: A control unit or pendant that allows operators to control the hoist's movement, including the speed and direction.

These hoists are commonly used in environments like factories, warehouses, construction sites, and ports for tasks such as lifting machinery, equipment, or cargo. They offer greater efficiency and precision than manual hoists and are available in various sizes and lifting capacities.

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Mox |

| Loading Capacity | 40-45Tons |

| Driven | Mechanical |

| Country of Origin | India |

| Power | 9-12kw |

| Automatic Grade | Semi Automatic, Automatic |

| Condition | New |

| Voltage | 440V |

| Application | Weight Lifting |

| Type | Electric Wire Rope Hoist |

| Delivery Time | 5-7 days |

| Packaging Details | Wooden box packing required. |

A base-mounted wire rope hoist is a type of lifting equipment that is mounted directly onto a base or a foundation structure, typically at the floor level or on a fixed platform. This design is commonly used in situations where overhead space is limited or unavailable, allowing the hoist to operate without requiring ceiling or overhead track systems. The hoist uses a wire rope to lift heavy loads and is designed for industrial and commercial applications. Key Features of Base Mounted Wire Rope Hoists: Mounting Design: Base-Mounted: The hoist is fixed to a solid base or platform at ground level or a lower position, which can be a concrete floor, a steel structure, or other stable foundations. This setup is useful in situations where overhead space is limited, or when the hoist needs to be placed in a specific location on the ground or floor level. Wire Rope Lifting Mechanism: The hoist uses a strong steel wire rope wound around a drum or pulley system to lift and lower loads. The wire rope is designed for high strength and durability, making it capable of handling heavy weights without compromising safety. The lifting mechanism can handle varying load capacities, typically ranging from a few tons to over 50 tons, depending on the specific hoist model. Electric Motor: A powerful electric motor drives the lifting mechanism, providing the necessary power to raise and lower heavy loads. The motor typically includes a gearbox for speed and torque control, allowing smooth and controlled lifting operations. The motor is generally mounted on the same base as the hoist, connected to the lifting drum via gears. Load Capacity: Base-mounted wire rope hoists are available in various load capacities, from smaller models for lighter loads (1-5 tons) to heavy-duty models that can lift loads of up to 100 tons or more, depending on the application. Braking System: Base-mounted wire rope hoists typically come with automatic braking systems that engage when the motor is turned off, ensuring that the load is securely held in place and preventing it from falling. This is a crucial safety feature, especially when working with heavy or potentially hazardous loads. Trolley Movement: In some models, the hoist may be mounted on a trolley that moves along a fixed track or beam, allowing horizontal movement of the load. The trolley can be motorized or manually operated, depending on the application and required load capacity. Control Systems: Pendant Controls: Operators can control the hoist using a pendant control, which is a wired device that allows the operator to lift, lower, and maneuver the load safely from a distance. Remote Controls: In some systems, wireless or radio frequency remote controls are used for more flexibility and to keep the operator at a safe distance from the load. Limit Switches: These are safety devices that stop the hoist when the load reaches its designated lifting or lowering limit, preventing over-travel and possible damage. Safety Features: Overload Protection: To prevent damage or accidents, these hoists often feature overload protection systems that automatically stop the hoist if the load exceeds its rated capacity. Emergency Stop: An emergency stop button is commonly included in the control system to immediately halt the hoist in case of an unexpected event or hazard. Applications of Base Mounted Wire Rope Hoists: Industrial Factories: Base-mounted wire rope hoists are commonly used in manufacturing facilities to lift and move heavy parts, tools, machinery, or raw materials, especially in areas with limited overhead space. Automotive and Aerospace: Used for lifting heavy automotive parts, engines, or machinery in workshops, assembly lines, and maintenance facilities.

| Business Type | Manufacturer, Supplier |

| Type | Electric Wire Rope Hoist |

| Application | Weight Lifting |

| Voltage | 440V |

| Condition | New |

| Automatic Grade | Semi Automatic |

| Power | 9-12kw |

| Country of Origin | India |

| Driven | Hydraulic |

| Loading Capacity | 20-25Tons |

| Brand Name | Mox |

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Mox |

| Loading Capacity | 5-10Tons |

| Driven | Mechanical |

| Country of Origin | India |

| Power | 9-12kw |

| Automatic Grade | Automatic |

| Condition | New |

| Voltage | 440V |

| Application | Weight Lifting |

| Type | Electric Wire Rope Hoist |

| Packaging Details | wooden box packing required |

An electric wire rope hoist is a mechanical lifting device that uses an electric motor to raise and lower loads using a steel wire rope. These hoists are widely used in various industrial applications due to their ability to lift heavy loads with precision and safety. They are commonly used in construction, manufacturing, warehouses, and many other industries where heavy-duty lifting is required. Key Features of Electric Wire Rope Hoists: Electric Motor: The electric motor powers the hoist and is responsible for lifting, lowering, and sometimes moving the load horizontally. Electric motors come in various power ratings, allowing the hoist to handle different load capacities, from lighter loads (under 1 ton) to heavy-duty models (up to 100 tons or more). Wire Rope: A strong steel wire rope is used to lift and lower the load. The rope is wound around a drum or pulley system and is designed to withstand significant tensile stress and wear, making it ideal for lifting heavy loads. The rope is typically made of high-tensile steel, which provides strength and durability for long-term use. Hoist Drum: The hoist drum is where the wire rope is wound and unwound during the lifting and lowering processes. The drum is connected to the electric motor and gearbox, which controls the movement of the wire rope. Gearbox: The gearbox controls the speed and torque of the motor, allowing precise control over the lifting and lowering process. It reduces the motor speed and increases torque, enabling the hoist to lift heavier loads more efficiently. Braking System: Electric wire rope hoists are equipped with automatic brakes to securely hold the load in place when the motor is turned off. The brake system is essential for safety, preventing the load from falling when the hoist is not in operation. Some hoists have multiple braking systems, including fail-safe and electromagnetic brakes. Control System: Pendant Control: The hoist is often operated using a pendant control with buttons or switches that allow the operator to lift, lower, and move the load with ease. The pendant is typically connected to the hoist with a flexible cable. Wireless Remote Control: In some cases, hoists are equipped with wireless remote controls, allowing the operator to control the hoist from a safe distance and reducing the risk of accidents. Limit Switches: These are safety devices that stop the hoist when the load reaches its maximum lifting height or when it is lowered to its lowest point, preventing over-travel and damage to the hoist or load. Trolley: Some electric wire rope hoists are mounted on a trolley system, allowing them to move horizontally along a beam or track. The trolley can be manually operated or motorized, depending on the hoist’s design and application. Overload Protection: Most electric wire rope hoists come equipped with overload protection mechanisms that prevent the hoist from lifting loads that exceed its rated capacity, reducing the risk of damage to the hoist and ensuring safety during operation.

| Business Type | Manufacturer, Supplier |

| Brand Name | Mox |

| Loading Capacity | 45-50Tons |

| Driven | Hydraulic |

| Country of Origin | India |

| Power | 1-3kw, 3-6kw, 6-9kw |

| Automatic Grade | Automatic |

| Condition | New |

| Voltage | 440V |

| Application | Weight Lifting |

| Type | Electric Wire Rope Hoist |

| Delivery Time | 5-7 days |

An Electrical Wire Rope Hoist is a lifting device that uses an electric motor to drive a wire rope to lift, lower, and move heavy loads in industrial and commercial environments. It is an essential piece of equipment in industries such as construction, manufacturing, and warehouses, where heavy lifting is required.

Key Features of Electrical Wire Rope Hoists:

-

Electric Motor:

- The electric motor is the driving force behind the hoist. It provides the power necessary to lift and lower heavy loads.

- It is usually designed for high-efficiency operation and may include speed control to adjust lifting speeds depending on the load and application.

-

Wire Rope:

- The hoist uses steel wire rope wound around a drum or pulley system. The rope is designed to lift heavy loads by unwinding from the drum during lifting and winding back during lowering.

- The wire rope is engineered to handle high tensile forces and is built to last, offering durability for heavy-duty operations.

-

Lifting Drum:

- The wire rope is wound around the lifting drum, which is connected to the electric motor. As the motor runs, it rotates the drum, either winding or unwinding the rope to move the load up or down.

-

Brake System:

- Most electric wire rope hoists are equipped with an automatic brake system that ensures that the load remains securely held in place when the motor is turned off.

- The brake prevents the load from falling unexpectedly and is an important safety feature, especially when lifting heavy objects.

-

Gearbox:

- The hoist uses a gearbox to control the motor’s speed and torque. It allows the hoist to lift heavy loads while operating at a controlled, safe speed.

- The gearbox helps reduce motor speed while increasing the torque, allowing the hoist to lift heavier loads with ease.

-

Control System:

- Pendant Controls: A standard feature for operating the hoist, allowing the operator to raise or lower the load via a wired pendant control.

- Remote Controls: Some hoists are equipped with wireless remote controls, providing greater flexibility and allowing the operator to control the hoist from a safe distance.

- Limit Switches: These prevent the hoist from over-traveling beyond its set lifting or lowering range, providing an added layer of safety.

-

Trolley:

- Some electrical wire rope hoists are mounted on a trolley, which allows horizontal movement along a beam or track. The trolley system enables precise control when moving loads across a factory or warehouse.

-

Overload Protection:

- Most electrical wire rope hoists include overload protection mechanisms, which prevent the hoist from lifting loads that exceed its rated capacity. This helps protect the hoist from damage and ensures safe operations.

-

Safety Features:

- Limit Switches: Automatically stop the hoist when it reaches its maximum or minimum limit, preventing damage to the hoist and the load.

- Emergency Stop: An emergency stop button or system to immediately halt the hoist operation if there is a malfunction or dangerous situation.

| Business Type | Manufacturer, Supplier |

| Type | Electric Wire Rope Hoist |

| Application | Weight Lifting |

| Voltage | 380V |

| Condition | New |

| Automatic Grade | Automatic |

| Power | 6-9kw |

| Country of Origin | India |

| Driven | Hydraulic |

| Loading Capacity | 45-50Tons |

| Brand Name | Mox |

| Business Type | Manufacturer |

| Brand Name | Mox |

| Loading Capacity | 5-10Tons |

| Driven | Mechanical |

| Country of Origin | India |

| Power | 1-3kw, 3-6kw |

| Automatic Grade | Automatic |

| Condition | New |

| Voltage | 440V |

| Application | Weight Lifting |

| Type | Electric Wire Rope Hoist |

| Delivery Time | 5-7 days |

| Packaging Details | wooden box packing required. |

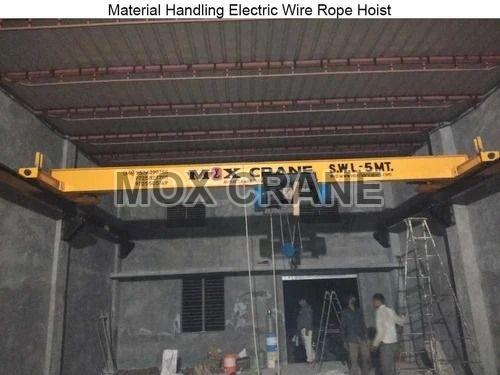

A Girder Electric Wire Rope Hoist is a type of electric hoist mounted on a girder (or beam), which is a structural component of an overhead crane system. This type of hoist combines the power and precision of an electric wire rope hoist with the flexibility and strength of a girder system, typically used for lifting and moving heavy loads in industrial environments. Key Features of a Girder Electric Wire Rope Hoist: Girder (Beam) Structure: The girder refers to the horizontal beam or track upon which the hoist moves. The girder is typically made of steel and is a critical component in supporting the hoist and the load it carries. It can be part of a larger overhead crane system, which may also include end trucks, trolleys, and other components that allow the hoist to travel along the length of the beam. Electric Wire Rope Hoist: The electric wire rope hoist is mounted onto the girder and is used to lift and lower heavy loads. The hoist is driven by an electric motor and uses a steel wire rope wound around a drum or pulley system to perform the lifting function. These hoists are capable of handling heavy loads with precision, and they can be used for a wide variety of lifting tasks in industrial and commercial settings. Motorized Trolley: Many girder-mounted electric wire rope hoists are equipped with a motorized trolley that allows the hoist to move along the girder. This enables the hoist to transport the load horizontally across a large area. The trolley may be driven by an electric motor and could be equipped with either a pendant control or wireless remote control to operate it. Lifting Capacity: Girder-mounted wire rope hoists are designed to handle a wide range of load capacities, typically from 1 ton to over 100 tons, depending on the specific model and application. The girder and hoist combination are designed to withstand the stresses associated with lifting heavy loads safely and efficiently. Precision Control: The hoist is operated using a control system that allows for precise lifting, lowering, and horizontal movement of loads. Controls typically include pendant control, wireless remote control, or other automation systems, allowing the operator to control the hoist from a distance. Some systems may also include variable speed control to adjust lifting speeds based on the load and application needs. Safety Features: Limit Switches: To prevent over-travel, limit switches automatically stop the hoist when it reaches the upper or lower limit of its range. Overload Protection: The hoist typically includes an overload protection mechanism to prevent lifting loads that exceed the rated capacity. Emergency Stop: A built-in emergency stop function halts the hoist operation immediately in case of an emergency or malfunction. Braking System: The hoist includes automatic brakes that engage when the motor is turned off, ensuring the load is held securely in place. Girder Design Variations: Single Girder: A single girder electric wire rope hoist system consists of one main girder supporting the hoist. This type is typically used for lighter to medium-duty applications and is more cost-effective. Double Girder: In this setup, two girders are used to support the hoist, providing extra strength and stability, making it ideal for heavier loads and more demanding operations. Double girder systems allow for greater lifting heights and better load distribution. Advantages of Girder Electric Wire Rope Hoists: High Lifting Capacity: Girder-mounted electric wire rope hoists are designed for heavy-duty applications and can handle significantly larger loads than standard electric hoists. These systems are ideal for lifting heavy industrial machinery, large components, and materials. Efficient Horizontal and Vertical Movement: The combination of vertical lifting by the hoist and horizontal movement by the trolley enables quick and efficient movement of loads across large areas.

| Business Type | Manufacturer, Supplier |

| Country of Origin | India |

| Warranty | 1year |

| Lift Speed | 3-4 Mpm |

| Power Source | 3 Phase Required |

| Color | Yellow, Black |

| Type | Heavy Duty Wire Rope Hoist |

| Application | Weight Lifting |

| Voltage | 440V |

| Condition | New |

| Automatic Grade | Automatic |

| Power | 9-12kw |

| Driven | Mechanical |

| Loading Capacity | 10-15Tons, 35-40Tons, 40-45Tons, 45-50Tons |

| Brand Name | Mox |

| Delivery Time | 3-5 days |

| Packaging Details | Wooden box packing required |

A heavy-duty wire rope hoist is a robust, industrial lifting device designed for handling extremely heavy loads. These hoists are commonly used in industries such as construction, manufacturing, shipbuilding, mining, and heavy-duty logistics, where large, bulky, or heavy materials need to be lifted and moved. Key Features of Heavy-Duty Wire Rope Hoists: High Load Capacity: Heavy-duty wire rope hoists are designed to handle loads ranging from several tons to over 100 tons or more. The exact lifting capacity depends on the hoist model, with larger units capable of lifting massive loads, making them ideal for large-scale industrial operations. Wire Rope Construction: The hoist uses a strong steel wire rope to lift heavy loads. The wire rope is designed for high tensile strength and durability, allowing it to bear heavy loads without compromising safety. The rope is wound around a drum or pulley system to lift and lower the load. Heavy-Duty Motor: A powerful electric motor drives the lifting mechanism. The motor is designed to withstand the intense workload, providing high torque to lift extremely heavy objects. These hoists often come with gearboxes to adjust speed and torque, allowing for controlled lifting and lowering. Advanced Braking System: Heavy-duty hoists are equipped with advanced brake systems to ensure that the load is securely held in place when the hoist is not in motion. The brake system prevents the load from dropping unexpectedly and is crucial for ensuring safety during operation, especially with heavy loads. Heavy-Duty Trolley and Beam: Heavy-duty hoists typically feature reinforced trolleys that move along an overhead beam or rail system. The trolley system allows the hoist to travel horizontally, giving it flexibility to move the load across a large area. The beams used for these hoists are designed to support the heavy weight and to provide stability during lifting operations. Speed Control and Precision: Heavy-duty wire rope hoists often feature variable speed controls for more precise lifting and lowering, which is especially useful for handling sensitive or large loads. Precision control systems help operators position loads exactly where they are needed with minimal risk of damage. Safety Features: Overload Protection: These hoists are typically equipped with overload protection systems to ensure that the hoist doesn’t lift loads that exceed its rated capacity, reducing the risk of accidents or equipment damage. Limit Switches: To prevent the load from traveling beyond the safe lifting or lowering height, limit switches are installed to automatically cut off the motor when the load reaches the end of its travel. Emergency Stop: Most hoists are equipped with an emergency stop button to quickly halt operation in case of an emergency. Components of a Heavy-Duty Wire Rope Hoist: Hoist Drum: The drum is where the wire rope is wound. It controls the upward and downward movement of the load by winding and unwinding the rope. Electric Motor: Powers the hoist and provides the necessary force to lift heavy loads. Motors are designed to handle heavy-duty applications and often come with thermal protection to prevent overheating. Gearbox: The gearbox reduces the motor's speed and increases the torque, which is necessary for lifting heavy loads. It plays an essential role in controlling the hoist's lifting and lowering speed. Hook: The hook is where the load is attached. It can come in various configurations, including fixed or swivel hooks, depending on the specific application. Braking System: The hoist is equipped with automatic brakes that hold the load securely when the motor is not running. The braking system is vital for ensuring the load remains stationary when desired. Control Panel: The operator controls the hoist using a pendant or a wireless remote control, with the ability to raise and lower the load and operate the trolley. Limit Switches: Prevents the load fr

| Business Type | Manufacturer, Exporter |

| Brand Name | Mox |

| Loading Capacity | 10-15Tons, 15-20Tons, 20-25Tons, 25-30Tons |

| Driven | Mechanical |

| Country of Origin | India |

| Power | 1-3kw, 3-6kw, 6-9kw, 9-12kw |

| Automatic Grade | Semi Automatic, Automatic |

| Condition | New |

| Voltage | 440V |

| Application | Weight Lifting |

| Type | Electric Wire Rope Hoist |

| Color | Yellow |

| Lift Speed | 3-4 mpm |

| Warranty | 1year |

| Delivery Time | 5-7 days |

| Packaging Details | Wooden packing |

A **low headroom wire rope hoist** is a type of hoist designed to work in areas where vertical space is limited. The key feature of a low headroom hoist is its compact design, which allows it to lift loads even in tight or constrained spaces where traditional hoists might not fit. These hoists are commonly used in factories, warehouses, and other environments with limited ceiling height.

### Key Features of Low Headroom Wire Rope Hoists:

1. **Compact Design**: The hoist and trolley are engineered to minimize the distance from the top of the beam to the hook, which is ideal for spaces with low ceiling heights.

2. **Efficient Lifting**: Like other wire rope hoists, low headroom hoists use a wire rope wound on a drum or a pulley system to lift and lower heavy loads.

3. **High Lifting Capacity**: Despite their smaller size, these hoists are still capable of handling heavy loads, depending on the model. They are typically rated for capacities ranging from 1 ton to several tons.

4. **Space Saving**: Low headroom designs make better use of available space, allowing for more efficient use of overhead clearance.

5. **Durability and Safety**: They come equipped with safety features like overload protection, limit switches, and emergency stop mechanisms to ensure safe operation.

6. **Motorized or Manual Operation**: Low headroom hoists can be motorized for automatic lifting and lowering, or they can be operated manually, depending on the requirements of the application.

### Applications:

- **Factories**: Particularly in facilities with low ceilings or where space is limited.

- **Warehouses**: Useful in narrow aisles or when clearance is tight.

- **Construction Sites**: For lifting materials in areas where overhead space is restricted.

### Benefits:

- **Maximized space efficiency**: By reducing the headroom required for installation, more space is available for movement or other operations.

- **Improved load handling**: Ideal for precise and controlled lifting of heavy loads in confined areas.

If you're considering purchasing or using a low headroom hoist, make sure to choose one with the right specifications for your lifting needs and space constraints.

| Business Type | Manufacturer, Supplier |

| Brand Name | Mox |

| Loading Capacity | 10-15Tons, 15-20Tons, 20-25Tons, 25-30Tons |

| Driven | Mechanical |

| Country of Origin | India |

| Power | 9-12kw |

| Automatic Grade | Automatic |

| Condition | New |

| Voltage | 440V |

| Application | Weight Lifting |

| Type | Electric Wire Rope Hoist |

| Color | Yellow, Black |

| Lift Speed | 3-4 mpm |

| Warranty | 1year |

| Delivery Time | 5-7 days |

| Packaging Details | Wooden packing |

Mox is a brand that manufactures industrial lifting equipment, including wire rope hoists. A **Mox wire rope hoist** is typically used in industries where heavy lifting and precise movement of loads are required. These hoists are designed to lift and lower loads using a wire rope that winds onto a drum, powered by an electric motor.

Here are some general features and benefits of Mox wire rope hoists:

1. **Heavy Duty Performance**: Mox hoists are built to handle heavy loads and offer high lifting capacities.

2. **Electric Powered**: They are usually electric-powered, offering smooth and efficient lifting operations.

3. **Durability**: Made from high-quality materials, Mox hoists are designed for long-lasting, reliable operation even in tough conditions.

4. **Safety Features**: These hoists typically include safety features like limit switches, overload protection, and emergency stop functions.

5. **Versatility**: Mox wire rope hoists can be used in a variety of industries, such as construction, manufacturing, warehouses, and more.

If you're looking for specific details, such as capacity ranges or installation instructions, it would be best to refer to the product manual or the manufacturer's website for more precise specifications.

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Mox |

| Loading Capacity | 10-15Tons, 5-10Tons |

| Driven | Mechanical |

| Country of Origin | India |

| Power | 9-12kw |

| Automatic Grade | Semi Automatic, Automatic |

| Condition | New |

| Voltage | 440V |

| Application | Weight Lifting |

| Type | Electric Wire Rope Hoist, Monorail Wire Rope Hoist |

| Delivery Time | 5-7 days |

| Packaging Details | Wooden box packing required |

A monorail wire rope hoist is a type of lifting equipment mounted on a single rail (monorail) that moves horizontally, typically used in applications where space is limited, or a straight-line lifting path is required. These hoists utilize a wire rope to lift heavy loads vertically while being mounted on a rail system for horizontal movement. Key Features of Monorail Wire Rope Hoists: Single Rail System (Monorail): The term "monorail" refers to the fact that the hoist is mounted on a single beam or rail, which allows it to travel horizontally along a fixed path. The monorail system can be installed on either overhead beams or tracks along the ceiling of the work area, making it ideal for confined spaces or areas where a straight-line lifting solution is needed. Wire Rope Lifting Mechanism: The hoist uses a steel wire rope wound around a drum or pulley system. This wire rope is responsible for lifting and lowering heavy loads. The rope is designed for high strength and durability, capable of handling substantial loads while minimizing wear. Trolley: The hoist is mounted on a trolley that moves along the monorail, allowing the load to be transported horizontally across the work area. The trolley may be motorized or manually operated, depending on the application and load capacity. Motorized trolleys are commonly used for smoother and faster operations. Electric Motor: A powerful electric motor drives the hoist mechanism. The motor powers both the lifting and lowering of the load, as well as the horizontal movement of the trolley along the monorail. These hoists may be designed for high-duty cycles and robust enough to handle continuous operation in industrial environments. Load Capacity: Monorail wire rope hoists can handle a wide range of lifting capacities, from lighter loads (around 1 to 5 tons) to heavy-duty loads (up to 50 tons or more), depending on the model. The design and construction of the hoist and monorail rail system determine the maximum lifting capacity. Compact and Efficient Design: These hoists are designed to be compact and space-efficient, making them suitable for smaller industrial spaces where a larger, more complex system would not fit. The simplicity of the monorail system makes it cost-effective compared to other crane systems with more intricate designs. Safety Features: Overload Protection: Monorail wire rope hoists are typically equipped with overload protection to prevent lifting loads beyond the hoist’s rated capacity. Limit Switches: These prevent the load from traveling beyond its designated lifting or lowering limit, helping avoid damage to the hoist or work area. Emergency Stop: An emergency stop button allows for quick halting of the hoist in case of an emergency. Brakes: These prevent the load from falling when the motor is turned off or in case of a power failure. Components of a Monorail Wire Rope Hoist: Hoist Drum: The hoist drum is where the wire rope is wound. It is responsible for raising and lowering the load. Wire Rope: A strong, high-tensile wire rope is used for lifting the load. The rope is typically made from steel and is designed for maximum durability and strength. Motor: The electric motor drives the hoist drum and, in some cases, the trolley. The motor allows for smooth lifting and horizontal movement of the load. Trolley: The hoist is mounted on a trolley that runs along the monorail. The trolley may either be manually operated or powered, depending on the model. Brakes: The braking system holds the load securely in place when the hoist is not operating, preventing any accidental dropping of the load. Limit Switches: These are safety devices that stop the hoist at predefined positions, ensuring that the load doesn't travel beyond the safe range. Control Pendant: The operator controls the hoist using a pendant control system, which may be wired or wireless. This provides control over lifting, lowering, and horizontal move

| Business Type | Manufacturer, Supplier |

| Brand Name | Mox |

| Loading Capacity | 10-15Tons, 15-20Tons, 5-10Tons |

| Driven | Mechanical |

| Country of Origin | India |

| Power | 3-6kw |

| Automatic Grade | Semi Automatic |

| Condition | New |

| Voltage | 440V |

| Application | Weight Lifting |

| Type | Electric Wire Rope Hoist |

| Delivery Time | 3-5 days |

| Packaging Details | Wooden packing required |

A motorized wire rope hoist is an industrial lifting device designed to lift heavy loads with the help of a wire rope and an electric motor. Unlike manual hoists, which require physical effort to operate, a motorized wire rope hoist uses an electric motor to raise and lower loads, making it more efficient for heavy-duty applications. Key Features of a Motorized Wire Rope Hoist: Electric Motor: The electric motor provides the power necessary to lift and lower the load, making the process faster and more efficient than manual operation. Motors are usually connected to a gearbox that helps in controlling the speed and torque of the hoist, allowing precise lifting and lowering. Wire Rope: A high-strength steel wire rope is used to lift the load. The wire rope is wound around a drum or a series of pulleys, allowing it to move vertically. Wire ropes are designed to handle large loads, making the hoist suitable for a variety of heavy lifting tasks. Load Capacity: Motorized wire rope hoists can typically handle a wide range of lifting capacities, from smaller hoists (around 1 ton) to heavy-duty models capable of lifting up to 100 tons or more. Trolley: The hoist is usually mounted on a trolley that runs along an overhead beam or rail system. This allows for horizontal movement of the load as well as vertical movement, enabling precise positioning of heavy objects. Trolleys can be motorized or manually operated depending on the application. Control System: Pendant control: A wired control is often used to operate the hoist from a safe distance. It allows the operator to control lifting, lowering, and trolley movement. Remote control: In some models, a wireless remote control system is available, which enables the operator to control the hoist from even further distances and reduces the risk of accidents. Limit switches: Safety limit switches are installed to prevent the load from moving beyond the safe limits of the hoist, preventing damage or accidents. Brakes: Motorized wire rope hoists typically include an automatic brake system that holds the load securely when the motor is not operating. The brakes are designed to engage quickly in case of a power failure or if the motor is turned off, ensuring the safety of the load. Speed Control: Some motorized wire rope hoists come with variable speed controls, which allow the operator to adjust the lifting speed based on the application’s requirements. This gives more precision when positioning loads. Components of a Motorized Wire Rope Hoist: Hoist Drum: The wire rope is wound around this drum as it is lifted or lowered. Motor: Powers the drum and the hoist system. Gearbox: Helps convert the motor’s rotational motion into lifting motion, controlling the speed and force applied to the load. Hook: Attached to the wire rope to lift the load. Safety Features: Including overload protection, emergency stop button, and limit switches to ensure safe operation. Types of Motorized Wire Rope Hoists: Monorail Hoists: These hoists are typically used on a single rail or beam, which limits the hoist to a specific direction of movement (usually horizontal). Double Girder Hoists: These hoists operate on a double beam system, which provides better stability and allows for higher lifting capacities and greater lifting heights. Under-slung Hoists: These are mounted underneath a beam or girder, ideal for locations where headroom is limited. Explosion-Proof Hoists: These are used in hazardous environments, such as chemical plants or oil rigs, where the potential for explosive materials or gases is high. They are designed to be safe under such conditions. Applications of Motorized Wire Rope Hoists: Manufacturing and Assembly Lines: Lifting heavy parts, machinery, or tools. Warehouses: Moving large packages or products. Construction Sites: Lifting heavy construction materials, such as steel beams, concrete panels, etc. Shipbuilding and Dockyards: Handling large sec

| Business Type | Manufacturer, Exporter |

| Warranty | 1year |

| Lift Speed | 3-4 Mpm |

| Power Source | 3 Phase Required |

| Color | Yellow |

| Type | Electric Wire Rope Hoist |

| Application | Weight Lifting |

| Voltage | 380V |

| Automatic Grade | Manual, Semi Automatic |

| Power | 3-6kw, 6-9kw |

| Country of Origin | India |

| Driven | Mechanical |

| Loading Capacity | 10-15Tons, 15-20Tons, 20-25Tons, 25-30Tons, 5-10Tons |

| Brand Name | MOX CRANE |

| Delivery Time | 3-5 days |

| Packaging Details | wooden box packing required. |

A single beam wire rope hoist is a type of lifting equipment used in industrial and construction settings to move heavy loads vertically. It typically operates on a single beam or girder and uses a wire rope to lift, lower, and move the load. These hoists are commonly used in workshops, warehouses, and other locations where lifting heavy equipment or materials is necessary.

Here are the key features and components of a single beam wire rope hoist:

Key Features:

-

Single Beam Configuration: The hoist is mounted on a single overhead beam (or girder), which supports the entire lifting mechanism. This makes it more space-efficient and cost-effective for certain applications compared to larger, more complex systems.

-

Wire Rope: The hoist uses a strong wire rope for lifting the load, which is wound around a drum or a pulley system. The wire rope is designed to handle significant weight, providing durability and reliability for heavy-duty operations.

-

Load Capacity: Single beam wire rope hoists typically have a lifting capacity ranging from a few tons up to 50 tons or more, depending on the model and application.

-

Compact and Lightweight: The design of a single beam hoist allows it to be more compact and lighter compared to other lifting equipment, making it ideal for smaller spaces or less heavy lifting tasks.

-

Motorized or Manual Operation: These hoists can be powered either manually or with an electric motor. Electric hoists are more common for heavier loads and continuous operation, while manual hoists may be used for lighter tasks.

Components:

-

Hoist Trolley: The hoist is mounted on a trolley that moves along the beam, allowing horizontal movement of the load.

-

Wire Rope Drum: This is the component around which the wire rope winds and unwinds, controlling the vertical movement of the load.

-

Hoist Motor: In powered versions, the hoist motor drives the drum to raise and lower the load. The motor typically has a gearbox for controlling speed and torque.

-

Limit Switches: These are safety devices that prevent the load from being raised or lowered beyond certain limits, ensuring safe operation.

-

Control System: Hoists are often equipped with either a pendant control or a wireless remote control to operate them from a safe distance.

Applications:

- Factories and Workshops: For lifting heavy equipment, machinery, and tools.

- Warehouses: To move pallets or large containers.

- Construction Sites: For lifting construction materials to higher levels of a building.

- Shipyards: To handle large parts for ships and marine equipment.

Advantages:

- Space-saving: The single beam design is less intrusive in terms of space, making it ideal for smaller workshops or areas with limited headroom.

- Efficiency: It can provide quick and efficient lifting in industrial applications.

- Cost-effective: Generally, a single beam hoist is a more cost-effective solution compared to more complex lifting systems.