- View Mobile Number

moxcrane@gmail.com

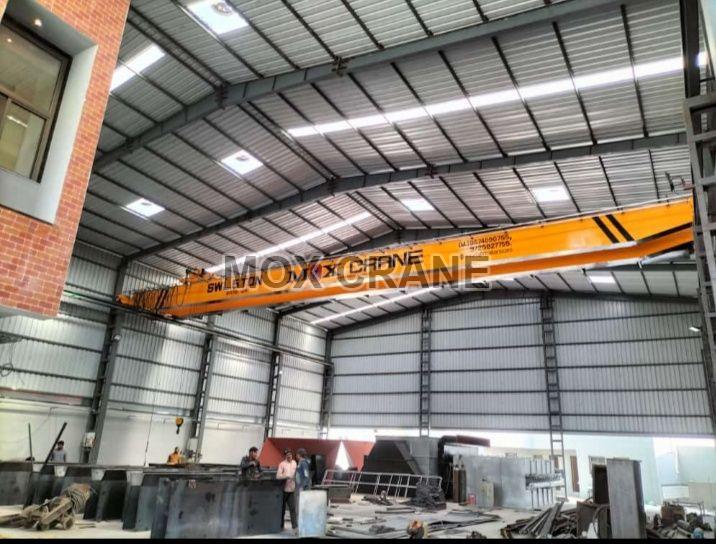

| Business Type | Manufacturer, Supplier |

| Brand Name | Mox |

| Country of Origin | India |

| Load Capacity | 10-15tons, 15-20tons, 20-25tons |

| Click to view more | |

Product Details

A Double Girder EOT Crane (Electric Overhead Traveling Crane) is a robust and heavy-duty crane system designed to handle a wide range of lifting applications, from medium to heavy-duty tasks. As the name suggests, this crane uses two parallel girders to support the trolley and hoist mechanism, allowing it to handle larger loads with enhanced stability, higher hook heights, and broader spans. Key Features of a Double Girder EOT Crane: 1. Design & Structure Two Parallel Girders: The crane features two strong girders that run along the length of the workspace or runway. These girders provide the necessary strength and load-bearing capacity required for heavy lifting. Bridge: The girders are connected by a bridge, which moves along the length of the runway (typically a set of rails or tracks) and carries the trolley and hoist. This allows the crane to travel across the area, lifting and moving heavy loads efficiently. Box or I-Beam Design: The girders are typically constructed as either box beams or I-beams, depending on the required strength. Box beams are stronger and provide better rigidity, which is ideal for heavy-duty applications, while I-beams are used for lighter tasks. 2. Load Capacity Heavy Load Handling: Double Girder EOT Cranes are designed to lift heavy loads, often ranging from 10 tons to several hundred tons, depending on the specific design and application. Lifting Capacity: The two-girder system provides enhanced support, allowing these cranes to carry significantly heavier loads compared to single girder cranes. This makes them ideal for industrial and manufacturing sectors. 3. Traveling Mechanism Trolley and Hoist System: The crane uses a hoist mounted on a trolley. The trolley moves horizontally along the girders while the hoist raises or lowers the load vertically. This combination provides precise control over both the lateral and vertical movement of the load. Electric Drives: Double Girder EOT Cranes are powered by electric motors, which provide the necessary force to move the bridge, trolley, and hoist. This allows for smooth, controlled, and energy-efficient operation. Traveling Speed: These cranes can have adjustable speed controls for both the trolley and bridge movements, making it easier to lift and position loads with precision. 4. Applications Manufacturing Plants: Used to move heavy raw materials, parts, and assemblies in factories, assembly lines, and production facilities. Steel Plants: In steel mills, these cranes are used to lift large steel ingots, billets, or coils. Construction Sites: They are often found on large construction sites for lifting and transporting heavy construction materials. Shipping Ports: Used for loading and unloading heavy cargo or containers at docks. Warehouses: Used to transport large or bulky materials within a warehouse environment. 5. Advantages Higher Load Capacity: Double girder cranes can lift heavier loads than single girder cranes, making them ideal for industrial applications that require lifting of substantial materials. Greater Lifting Height: Double girder cranes typically have a higher lifting height (hook height), which allows them to lift materials to greater vertical distances. Increased Span: These cranes can span a larger area compared to single girder cranes, enabling them to cover more floor space. Improved Stability: The two-girder design offers better stability and load distribution, ensuring safe operation, especially for heavy loads or materials that are difficult to move. Better Utilization of Space: The crane’s design makes efficient use of the available height and width in the facility, improving material handling capabilities in large industrial setups. 6. Safety Features Overload Protection: To prevent lifting loads beyond the crane's capacity, an overload protection system is included. This helps protect the crane and operator from accidents and equipment damage. Limit Switches: Limit swit